PackTech Filling Services: Keeping Your Filling Systems Running Efficiently

Comprehensive Maintenance & Support

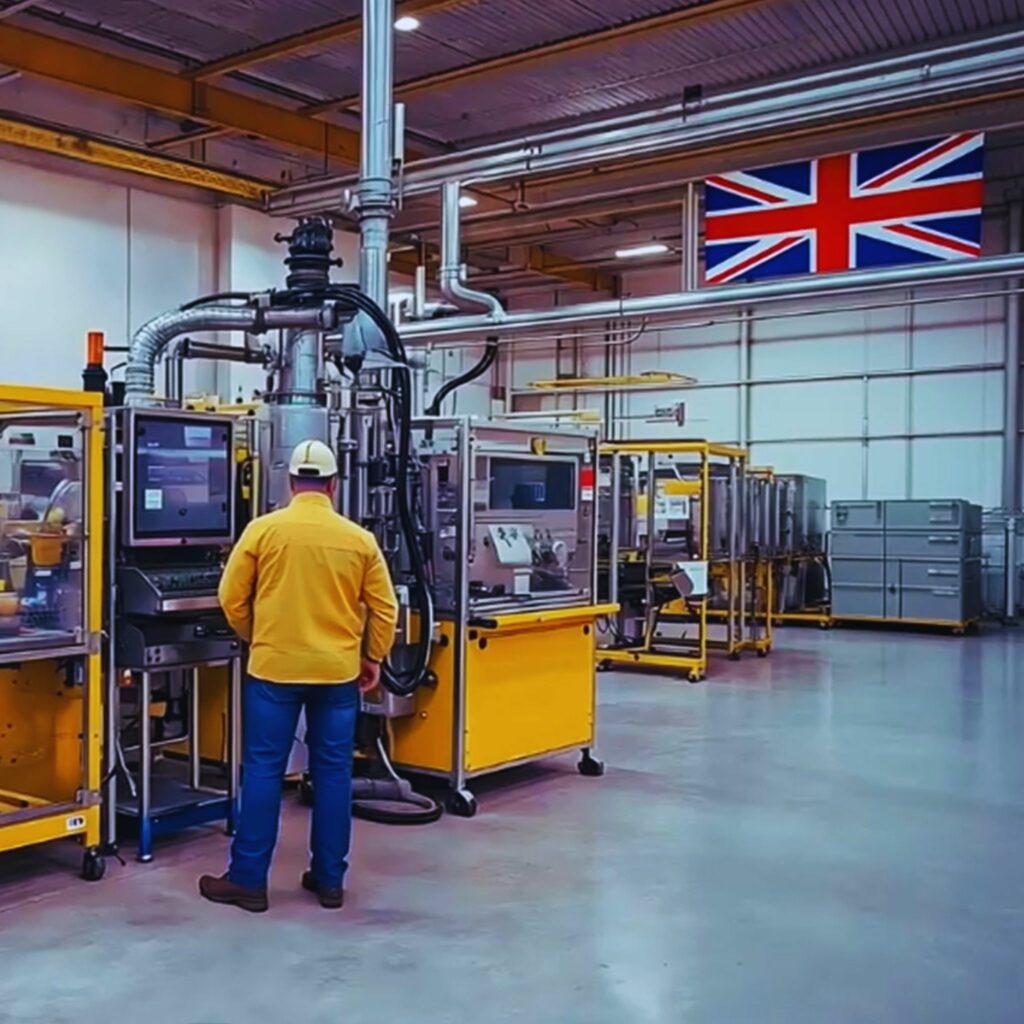

At PackTech, we understand that your business depends on the seamless operation of your filling machines and that’s why we offer specialized maintenance services to ensure our customers get the most out of their equipment. Whether you need routine check-ups, troubleshooting, or emergency repairs, our expert technicians are here to keep your PackTech systems running at peak performance.

Why Choose PackTech for Maintenance?

With PackTech Maintenance Services, you benefit from our extensive expertise and commitment to efficiency. Our engineers and technicians specialize in PackTech machines, providing in-depth knowledge and precise troubleshooting. We offer preventative maintenance programs to detect potential issues before they escalate, minimizing downtime and repair costs. Our team is dedicated to quick response times, ensuring that any issue is addressed promptly to keep your operations running smoothly. We use only genuine PackTech parts and components, guaranteeing reliability and compliance with industry standards. Above all, we strive to minimize production disruptions, allowing your filling operations to remain efficient and cost-effective.

What Our Maintenance Service Covers:

- Full system diagnostics to detect early wear and tear.

- Calibration of weighing and flow control systems to maintain precision in filling operations.

- Inspection of seals, valves, and nozzles for potential leaks or malfunctions.

- Software and automation system checks to ensure proper machine response.

- Replacement of worn-out components before they affect production.

- Cleaning and lubrication of essential moving parts to maintain smooth operation.

With PackTech Maintenance Services, you don’t have to worry about unexpected breakdowns. Our team ensures your filling system is always ready to perform at its best!

Refurbishment & Upgrades: Extending the Life of Your Equipment

Filling technology is always evolving, and equipment that was cutting-edge years ago may now be outdated. Instead of replacing an entire system, PackTech Filling offers refurbishment services to modernize your existing machines. If your filling equipment is slowing down, experiencing inefficiencies, or simply showing signs of age, our team can upgrade, recondition, and restore it to optimal functionality.

Why Refurbish Instead of Replace?

- Cost Savings: Upgrading your existing PackTech machine can be a more affordable alternative to buying a brand-new system.

- Extended Equipment Lifespan: Proper refurbishment can add years to your system’s life, delaying the need for major investments.

- Enhanced Performance & Efficiency: Upgrading key components can improve speed, accuracy, and energy efficiency.

- Adaptation to New Regulations: Industries such as pharmaceuticals, food processing, and chemicals frequently update compliance requirements meeting the latest safety and regulatory standards.

What Our Refurbishment Service Covers:

We offer comprehensive services to optimize your equipment’s performance. Our component replacement and reconditioning services involve replacing worn-out or outdated parts, such as pumps, valves, seals, and control systems. We also provide software and automation upgrades, installing the latest technology to enhance precision, reliability, and ease of operation. If your production demands have grown, we can increase filling speeds to meet your output needs through capacity and speed enhancements. Additionally, we can modify your system for versatility and adaptability to accommodate new types of liquids or containers. Before returning your refurbished system, we conduct full system testing and certification, performing extensive performance and safety checks to ensure it meets our high standards.

A Sustainable Approach

At PackTech, we believe in sustainability and cost-effective solutions. By refurbishing your existing machines, you’re reducing waste and minimizing unnecessary capital expenditures. Our goal is to help you maximize the value of your investment while ensuring your operations remain up to date.

Why Trust PackTech for Maintenance & Refurbishment?

Decades of industry experience in filling technology.

Specialized knowledge of PackTech machinery.

Commitment to safety, efficiency, and compliance.

Fast turnaround times to keep your production moving.

Customer-focused service tailored to your needs.

Get in Touch

If your PackTech filling system needs servicing, maintenance, or refurbishment, our team is ready to help.

Contact us today to schedule an assessment or consultation, and let’s ensure your filling operations remain safe, efficient, and productive!